ACO Drainage System Assessment

The DSA identifies drainage issues found and describes their impact on production from the point of view of:

- Hygiene

- Safety (employee health and safety, and product safety risks)

- Operations (production continuity risks)

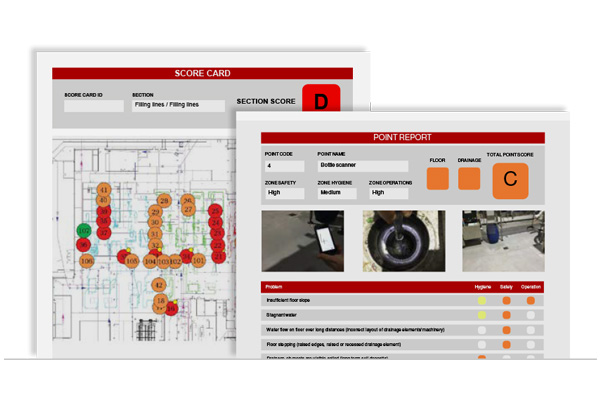

The ACO Drainage System Assessment (ACO DSA) comprises a complex evaluation of the existing drainage system and surrounding environment including production and service technologies and its impact on potential risks within food precessing plants. This evaluation also covers risks arising from drainage integration, and floor and wall quality.

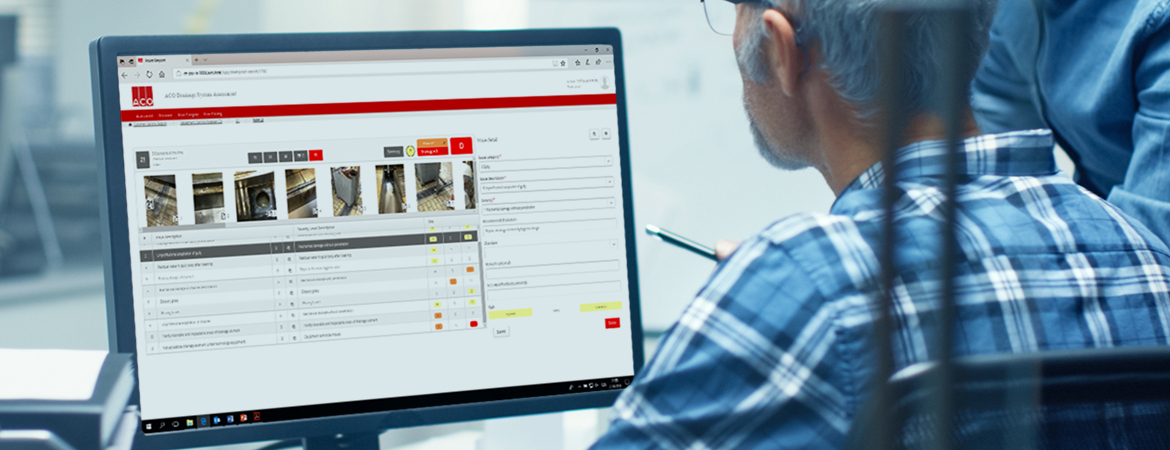

The opinions of our expert team, the views of the client, local experience and industry best practice are considered when identifying current and potential risks. Any issues found are processed by means of ACO‘s original software applications and a Corrective Action Plan is released to minimise all risks, develop more effective maintenance schedules and, if required, propose future investments to the client.

DSA is an independent consultative activity. Our service team is capable to assess the food production environment with focus on drainage system, floors, walls, general cleanliness and facility (technology) layout. There are three main aspects assessed: Hygiene, Safety (Health and Safety and Food Safety) and Operation (Operational Continuity). Based on these findings our service team generates a protocol and recommends a corrective action plan.

Benefits

DSA is an independent observation and evaluation of entire food production process especially in regard of wastewater management and its interaction with drainage system. The outcome of the DSA is a comprehensive report and corrective action plan (CAP) that enables:

- Better understanding of drainage system function/malfunction

- Definition of weak points (nonconformities) in production area in regard of Hygiene, operator’s Safety and Operation – production/business continuity

- Definition of corrective action plan with basic timeline (urgent, midterm, long-term)

- Definition of standard solutions/action (e.g. set up SOP, basic maintenance, simple refurbishment projects etc.)

- Definition of customized solutions based on current situation on customer site that reflects facility and production layout, production schedule, CAPEX, hygienic standards/requirements….